ASTM A213, A269 904L ea tšepe e sa hloekang e kopantsoeng ka tubing Chaena

Alloy 904L ke tšepe e sa tsitsang, e phahameng ea alloy austenitic e nang le khabone e tlase.E sebelisoa haholo lits'ebetsong moo thepa ea kutu ea TP316/L le TP317/L e sa lekaneng.Alloy e boetse e fana ka sebopeho se setle haholo, ho cheseha le ho tiea.Ho eketsoa ha koporo ho fana ka lisebelisoa tse thibelang ho bola tse 904L tse phahametseng litšepe tse tloaelehileng tsa chrome nickel.Mehlala e kenyelletsa ho hanyetsa sulfuric, phosphoric, le acetic acid.

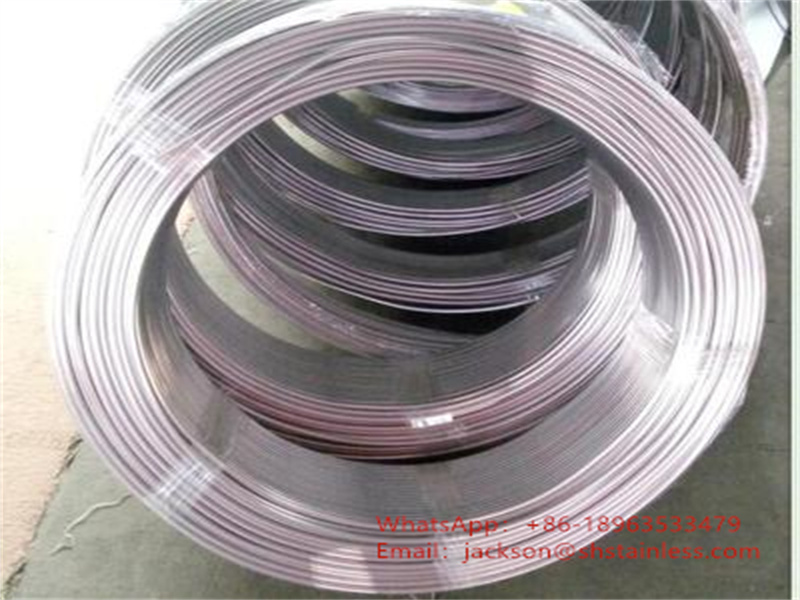

Boholo Range

| Kantle ho Diameter (OD) | Botenya ba Lerako |

| .250”–1.000” | .035″–.065″ |

Cold e felile le e khanyang annealed tube.

Litlhoko tsa Lik'hemik'hale

Alloy 904L (UNS N08904)

Moetso %

| C Khabone | Mn Manganese | P Phosphorus | S Sebabole | Si Silicone | Cr Chromium | Ni Nickel | Mo Molybdenum | N Naetrojene | Cu Koporo |

| 0.020 max | 2.00 max | 0.040 boholo | 0.030 boholo | 1.00 max | 19.0–23.0 | 23.0–28.0 | 4.0–5.0 | 0.10 max | 1.00–2.00 |

Dimensional Tolerances

| OD | OD Mamello | Mamello ea Lerako |

| ≤ .500″ | ± .005” | ± 15% |

| 0.500”–1.500” | ± .005” | ± 10% |

Thepa ea Mechini

| Kotulo e Matla: | 31 ksi mets |

| Matla a tšepe: | 71 ksi mets |

| Elongation (metsotso 2″): | 35% |

| Ho thatafala (Rockwell B Scale): | 90 HRB max |

Boqapi

Alloy 904L ha e na makenete maemong ohle 'me e na le sebopeho se setle haholo le ho cheseha.Sebopeho sa austenitic se boetse se fana ka boemo bona bo thata haholo, esita le ho fihlela mocheso oa cryogenic.

Lisebelisoa tsa indasteri

Mokhoa oa lik'hemik'hale

Lintho tsa eona tse phahameng tsa chromium le nickel, hammoho le tlatsetso ea molybdenum le koporo, motsoako oa 904L o thusa ho ema ho sulfuric, phosphoric le acetic acid.Sena se bohlokoa haholo tlhahisong ea li-acids le menontsha.

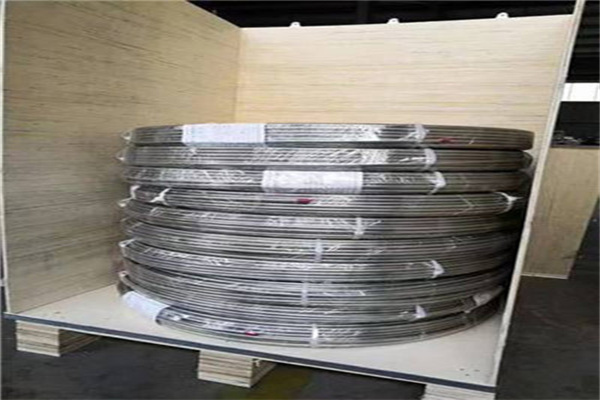

Ngola molaetsa wa hao mona mme o re romele wona